India has taken a monumental leap towards achieving semiconductor self-sufficiency with the approval of three semiconductor plants. The first-of-its-kind semiconductor fabrication plant (Fab) will be established in Dholera, Gujarat, through a collaboration between Tata Electronics and Taiwan’s Powerchip Semiconductor Manufacturing Corp. (PSMC). Let’s delve into the details of this transformative development.

India’s First Semiconductor Fab facility under the Semicon India Programme to be set up in Dholera Special Investment Region, Gujarat by Tata Electronics Pvt. Ltd. in partnership with Powerchip Semiconductor Manufacturing Corp, Taiwan. #CabinetDecision #DigitalIndia #SemiconIndia pic.twitter.com/TDNvocGfxS

— Ministry of Electronics & IT (@GoI_MeitY) February 29, 2024

Key Points:

Semiconductor Revolution: India approves the establishment of three semiconductor plants, a crucial step towards self-sufficiency in chip manufacturing.

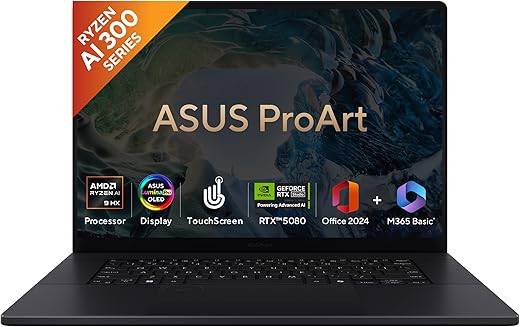

Tata-PSMC Collaboration: Tata Electronics and Taiwan’s PSMC joined forces to build India’s first semiconductor fabrication plant (Fab) in Dholera, Gujarat.

Strategic Investments: The collaboration between Tata and PSMC involves a substantial investment of Rs 91,000 crore, reflecting confidence in India’s potential as a semiconductor manufacturing hub.

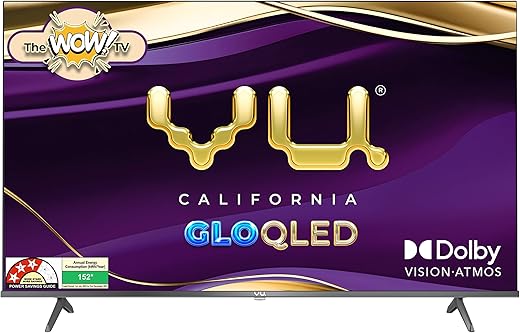

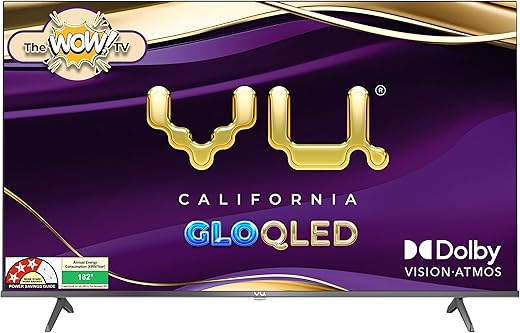

Diversification of Facilities: Two additional semiconductor plants were approved in Assam and Gujarat, with Tata Semiconductor Assembly and Test Pvt. Ltd. and CG Power partnering with Renesas for these ventures.

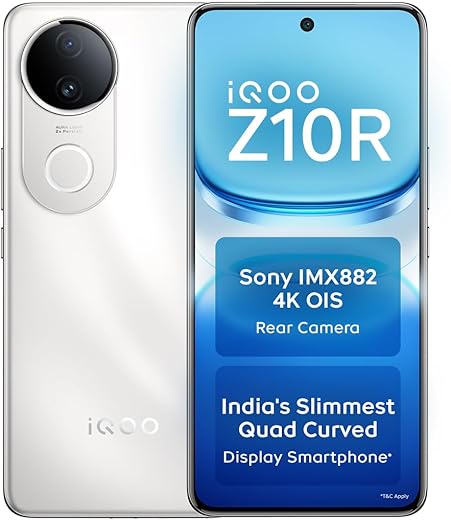

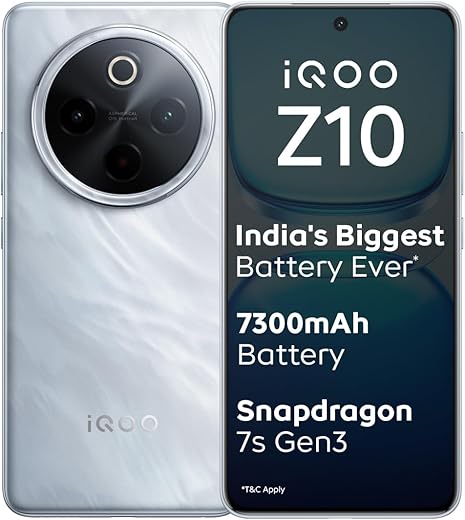

‘Made in India’ Smartphone Vision: The semiconductor facilities are a key step towards realizing the ‘Made in India’ vision, paving the way for genuinely indigenous smartphones.

Government Initiatives: The government implements a production-linked incentive (PLI) scheme, aiming to attract major players from global semiconductor manufacturing hubs.

Global Ecosystem Development: India’s semiconductor initiatives align with efforts to establish a robust ecosystem by attracting key players from China, South Korea, Taiwan, and the US.

Features:

Dholera Semiconductor Fab: Tata and PSMC’s collaboration in Dholera involves cutting-edge semiconductor fabrication, contributing significantly to India’s global standing in chip manufacturing.

Assam Chip Assembly and Testing Unit: Tata Semiconductor Assembly and Test Pvt. Ltd. secures approval for a chip assembly and testing unit in Assam, marking diversification in semiconductor capabilities.

Gujarat Semiconductor Plant: CG Power and Renesas collaborate on a semiconductor plant in Gujarat’s Sanand, contributing to the production of 15 million chips per day.

True ‘Made in India’ Devices: The semiconductor facilities aim to bridge the gap between assembled and truly ‘Made in India‘ smartphones, emphasizing indigenous manufacturing.

PLI Scheme: The government’s production-linked incentive (PLI) scheme is a catalyst for attracting major component players, fostering growth in the electronics manufacturing sector.

Union cabinet approves 3 semiconductor units under the India Semiconductor Mission. A giant leap towards realising PM Shri @narendramodi Ji’s vision of "Make in India, Make for the World".#CabinetDecision pic.twitter.com/NAtE48rInt

— Ashwini Vaishnaw (@AshwiniVaishnaw) February 29, 2024

Made in India Vision:

The semiconductor plants, especially the collaboration between Tata and PSMC, signify a pivotal moment in India’s pursuit of technological self-sufficiency. The ‘Made in India’ vision goes beyond assembly, with these facilities paving the way for true manufacturing on Indian soil. The strategic investments, coupled with government initiatives, demonstrate a comprehensive approach to establishing a robust ecosystem for semiconductor production. This vision aligns with the global trend of localization in manufacturing and positions India as a significant player in the semiconductor value chain.

Conclusion:

With the approval of three semiconductor plants, India is set to redefine its role in the global semiconductor landscape. The Tata-PSMC collaboration in Dholera, along with the facilities in Assam and Gujarat, represents a concerted effort towards semiconductor self-sufficiency. These initiatives not only contribute to the ‘Make in India’ vision but also have the potential to transform India into a prominent player in global semiconductor manufacturing. The strategic investments, government support, and a focus on fostering a comprehensive ecosystem are indicative of a future where cutting-edge technology is not just adopted but innovated and manufactured within the country. This marks a significant step towards true technological independence for India.

Follow Before You Take on Facebook | Twitter | WhatsApp Channel | Instagram | Telegram | Threads, For the Latest Technology News & Updates | Latest Electric Vehicles News | Electronics News